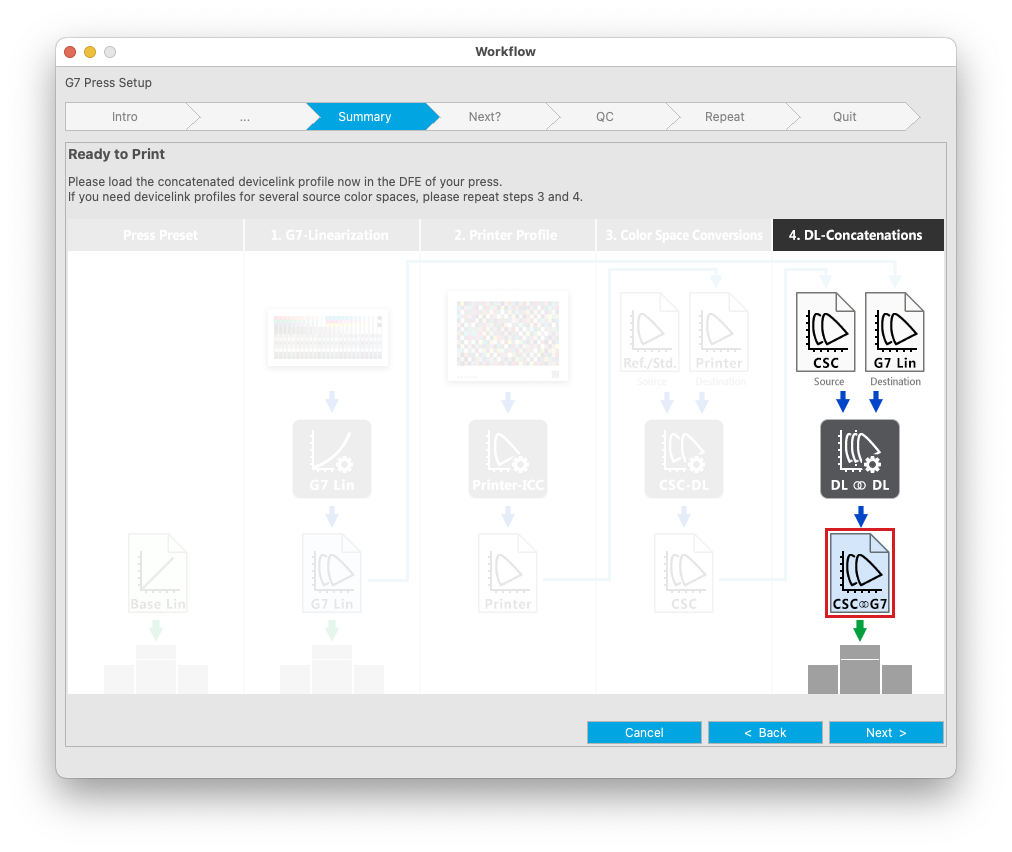

The output result when printing the same file on different machines does not look identical. To achieve identical results the input data has to be converted using a color management system.

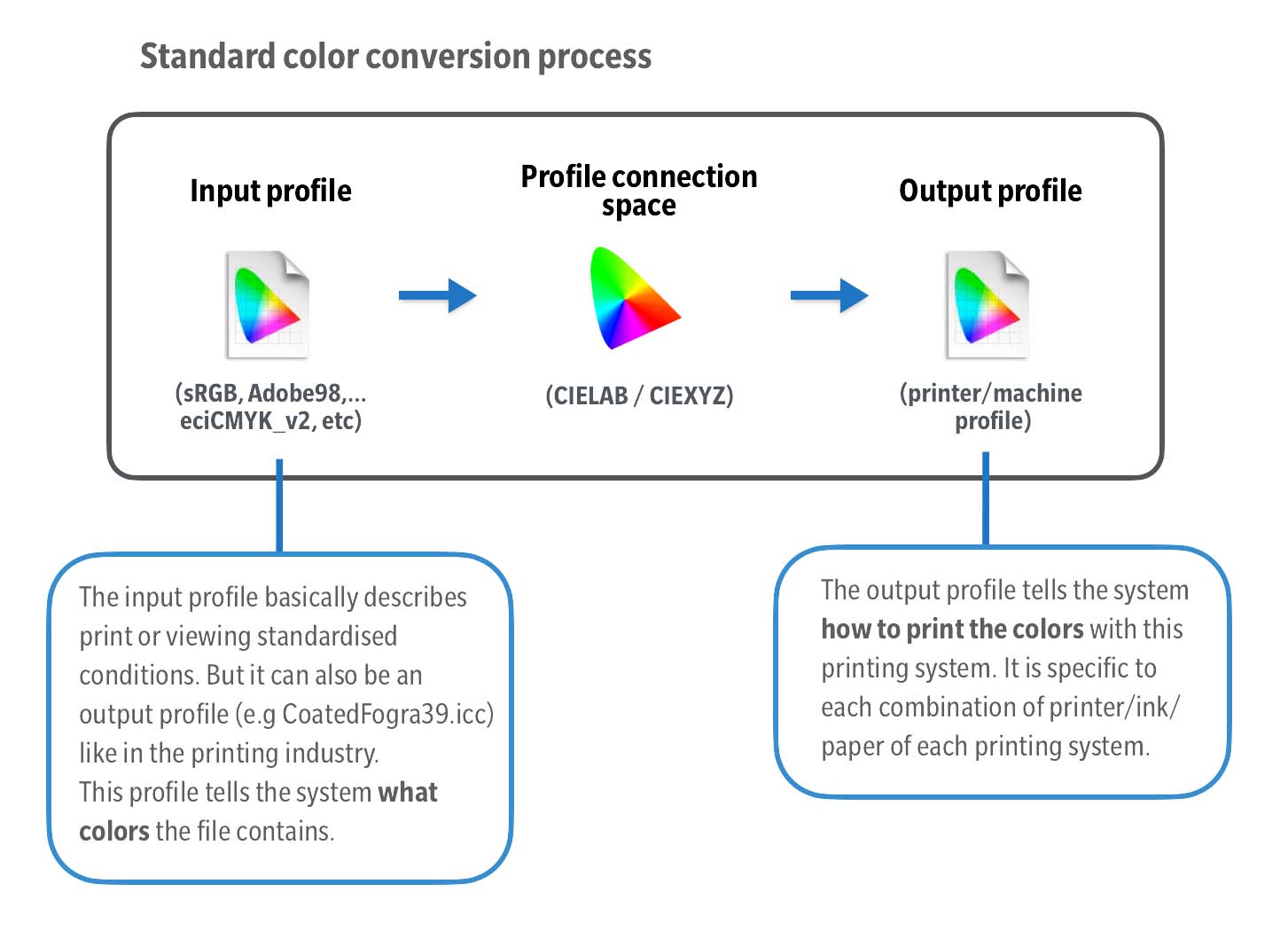

The color conversion is typically done using ICC-Profiles which are used to perform a conversion from input device data (such as RGB) to output device data (such as CMYK) using a translation color space. This translation space is usually CIELAB and known as PCS (Profile Connection Space).

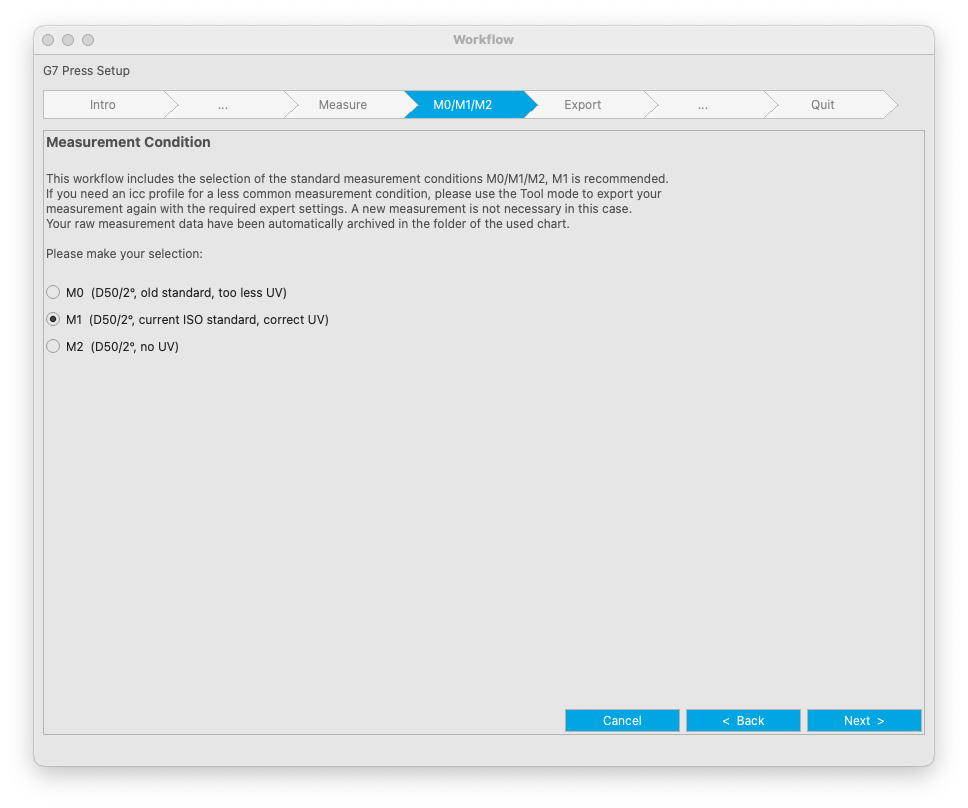

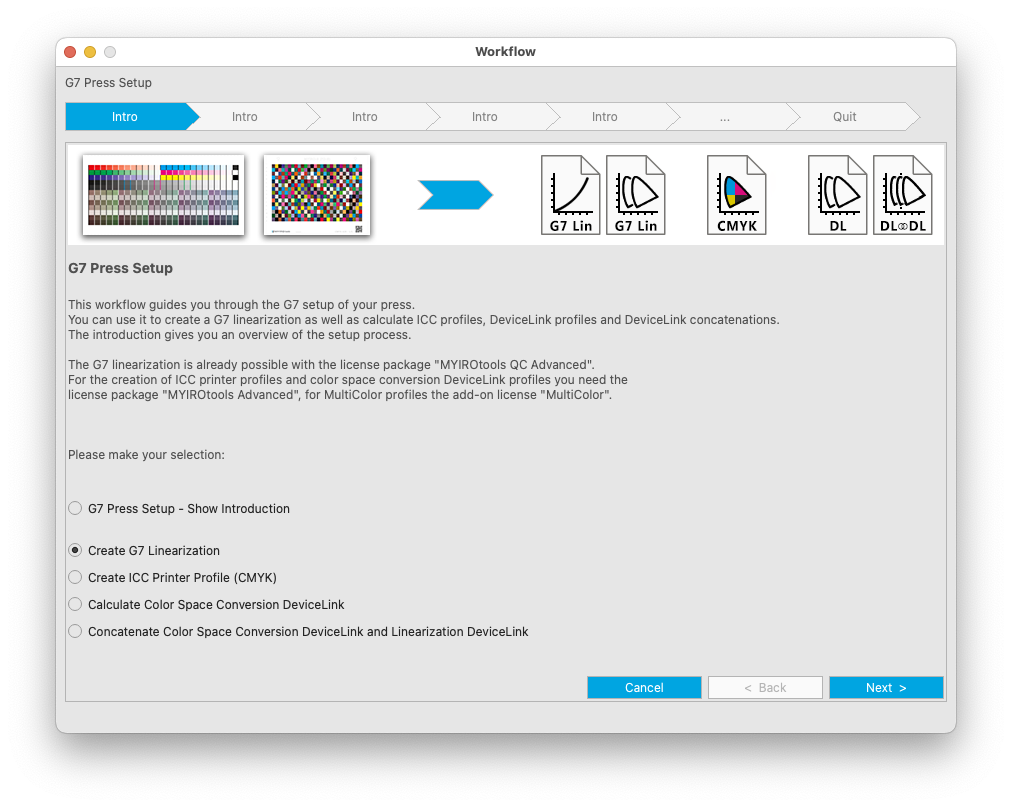

In todays print workflows digital input files such as PDF files are converted in systems called a RIP, DFE (Digital Front End), Controller or similar. To achieve good conversion speeds the accuracy is often limited to 8Bit. This limitation is not a problem in practice if the machine is brought into a "linear" state. Thanks to this linearization the necessary corrections to achieve accurate color output is minimized and the available 256 steps per channel (8 Bit) are enough.

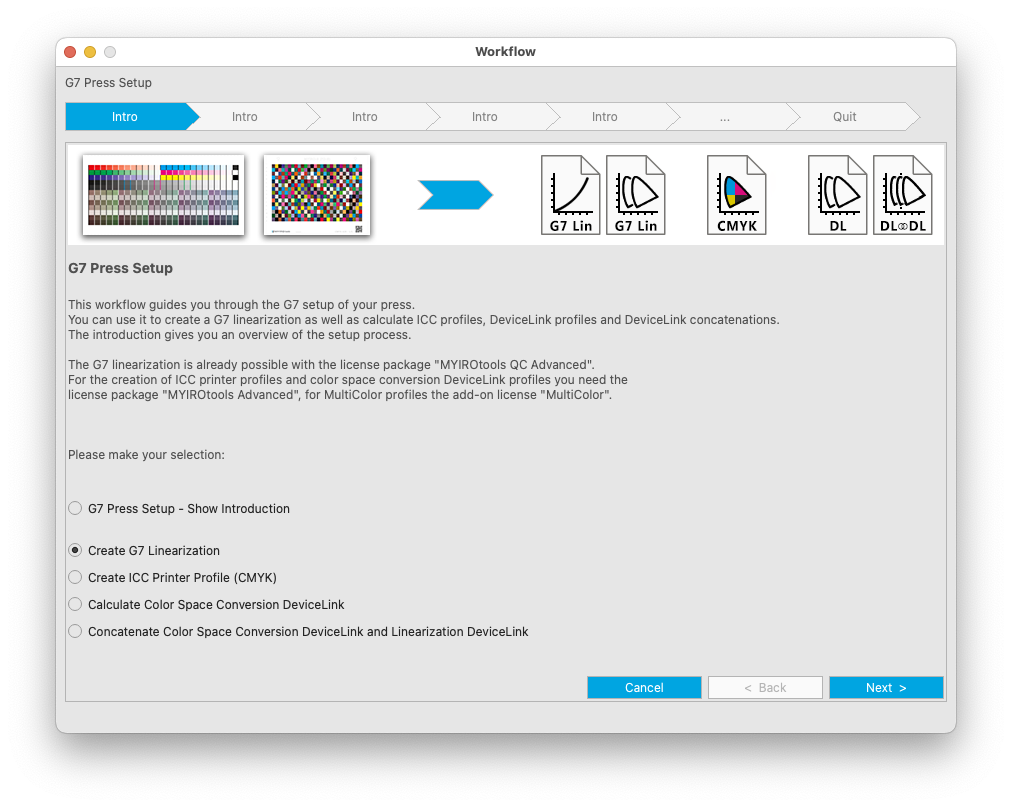

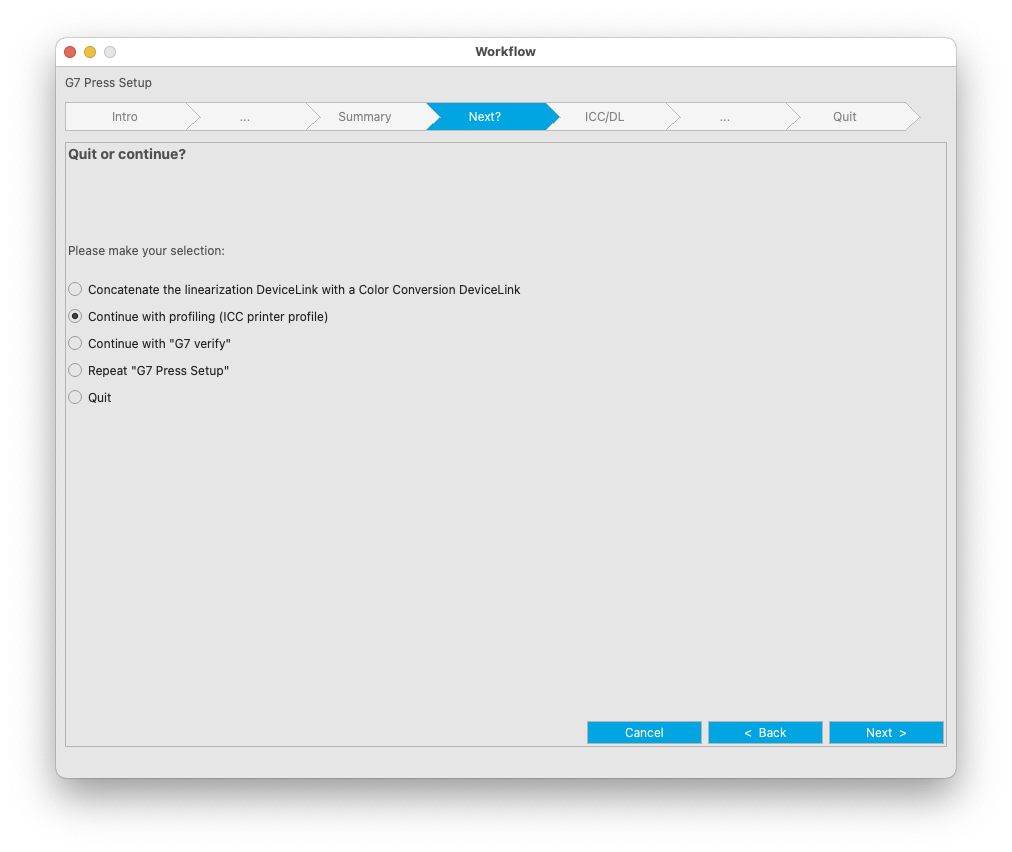

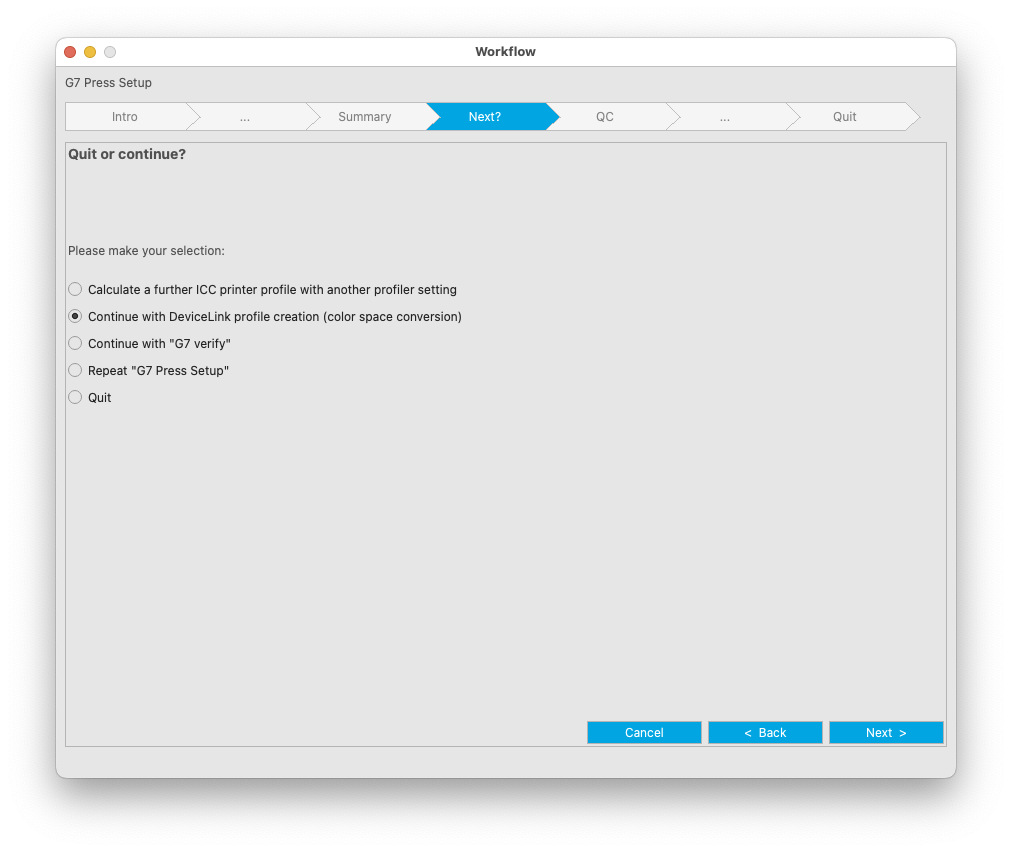

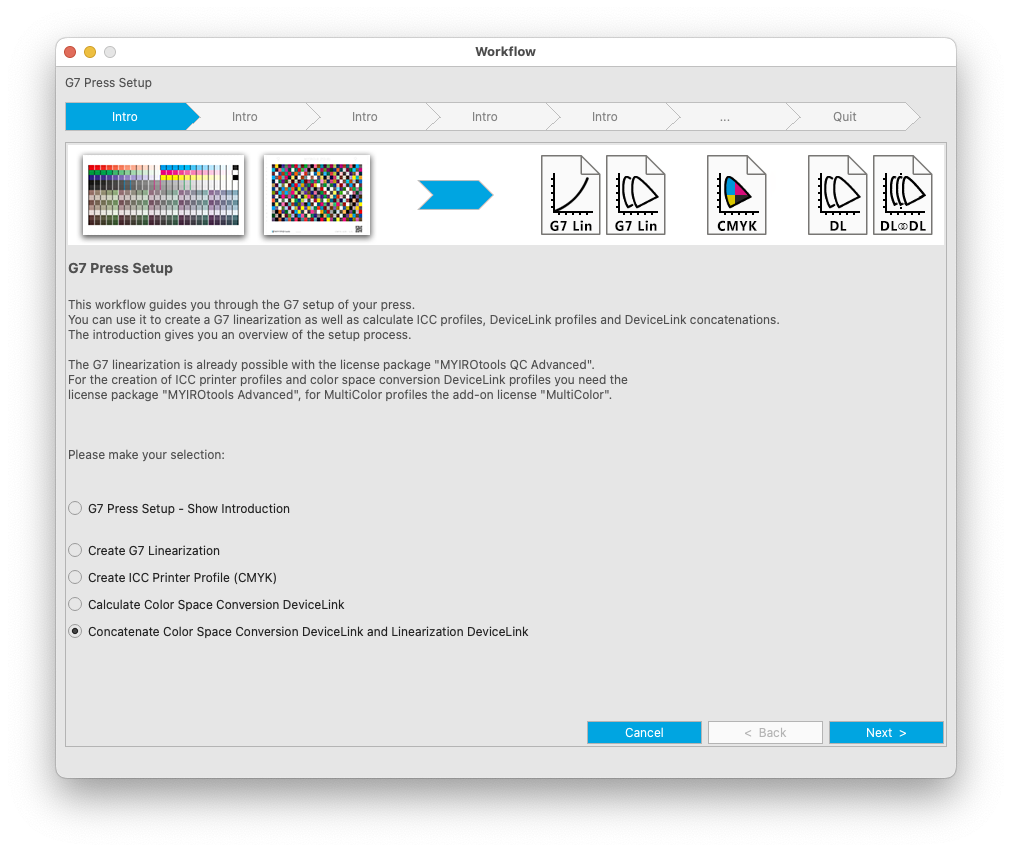

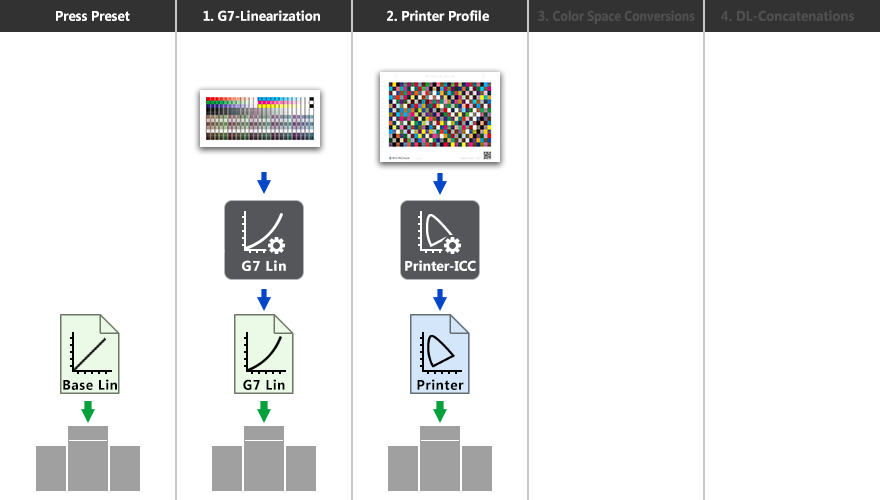

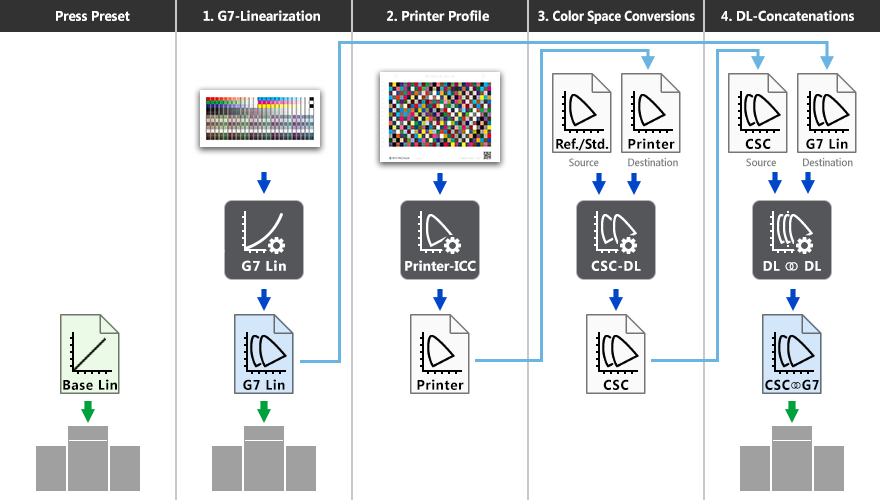

Method 1.

G7 Curves applied in Controller

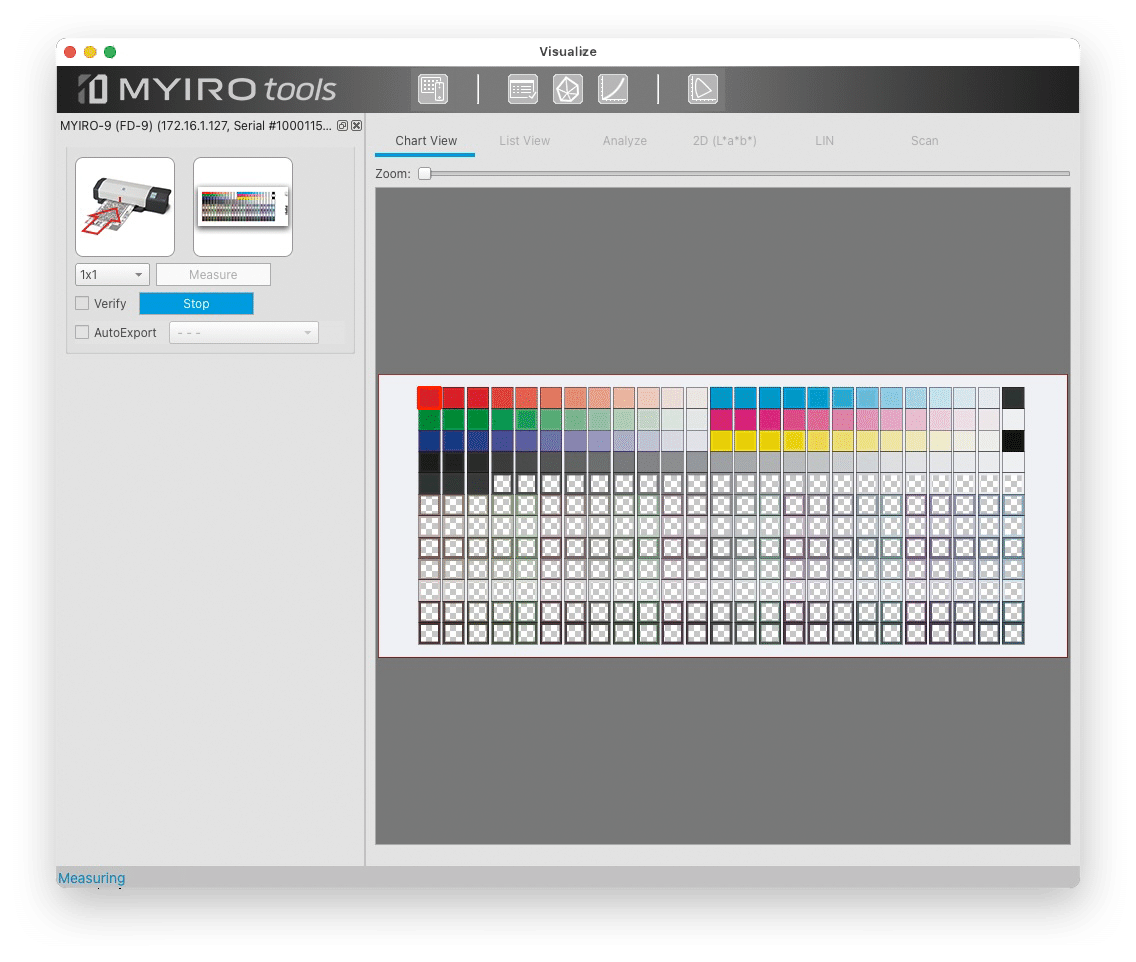

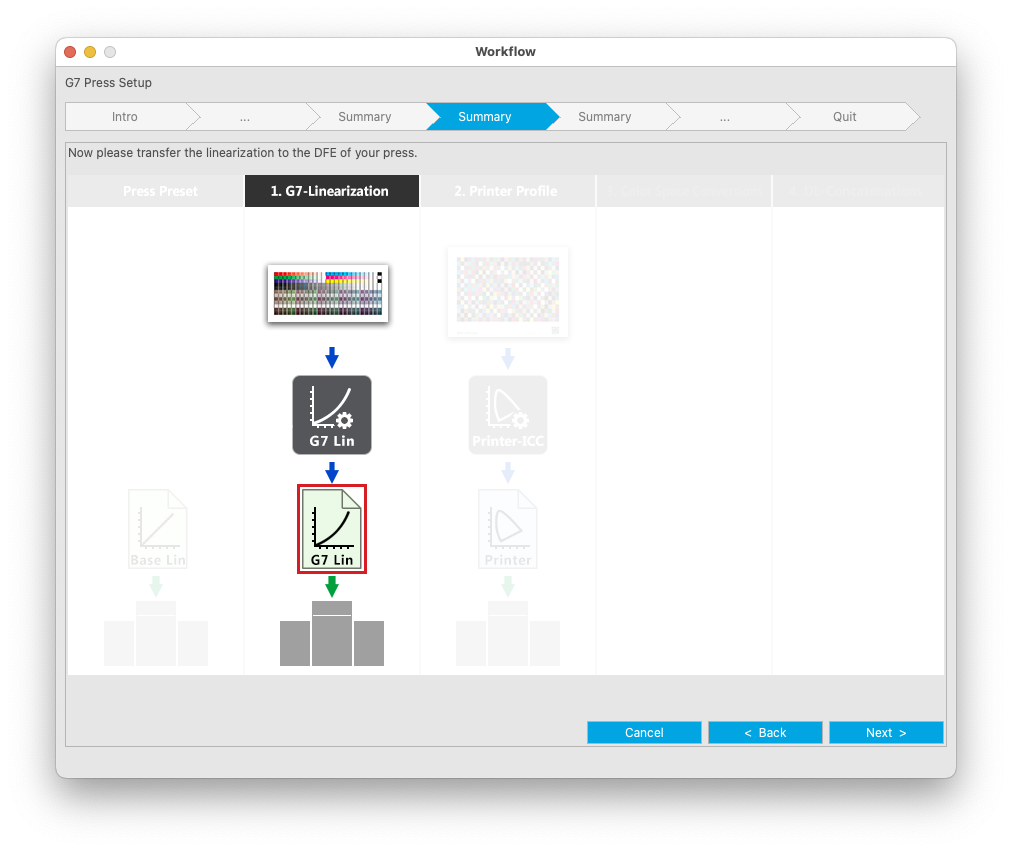

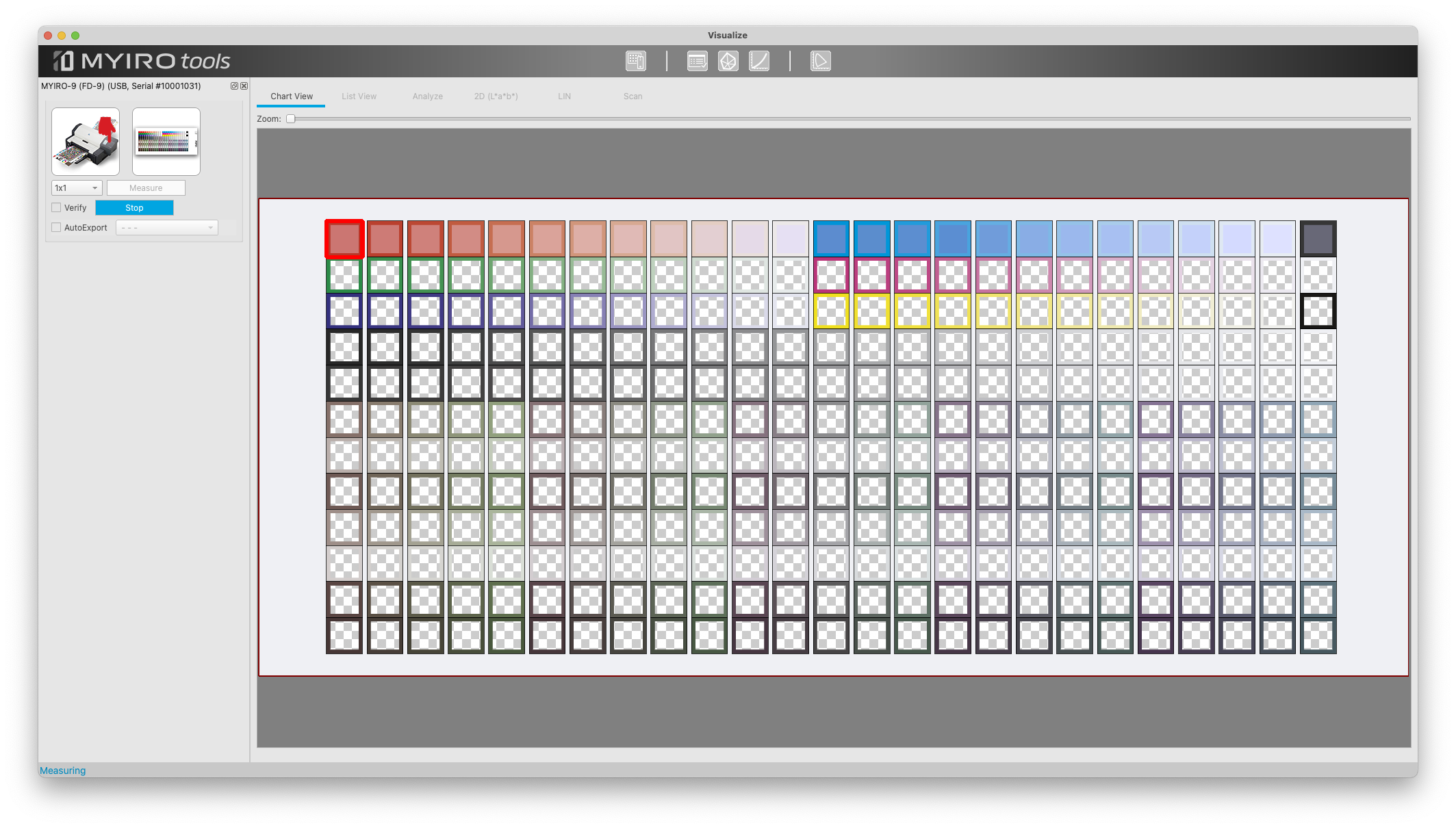

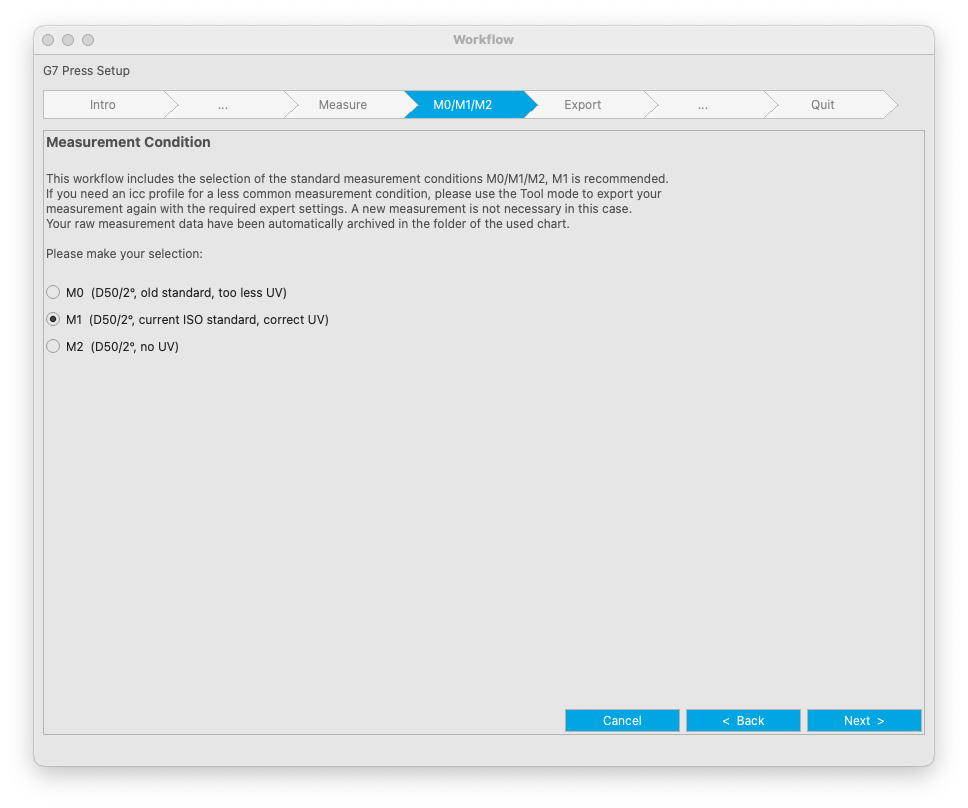

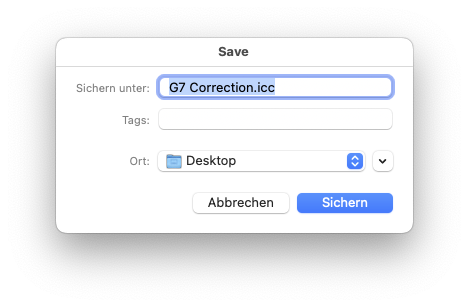

MYIROtools generates one correction curve per output channel. These curves are used to make sure that the output of the press before any color conversion is applied meets the requirements of the G7-methodology.

The curves can be loaded into the controller of many types of printing machines.

Method 2.

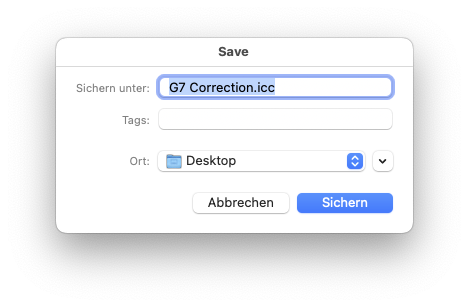

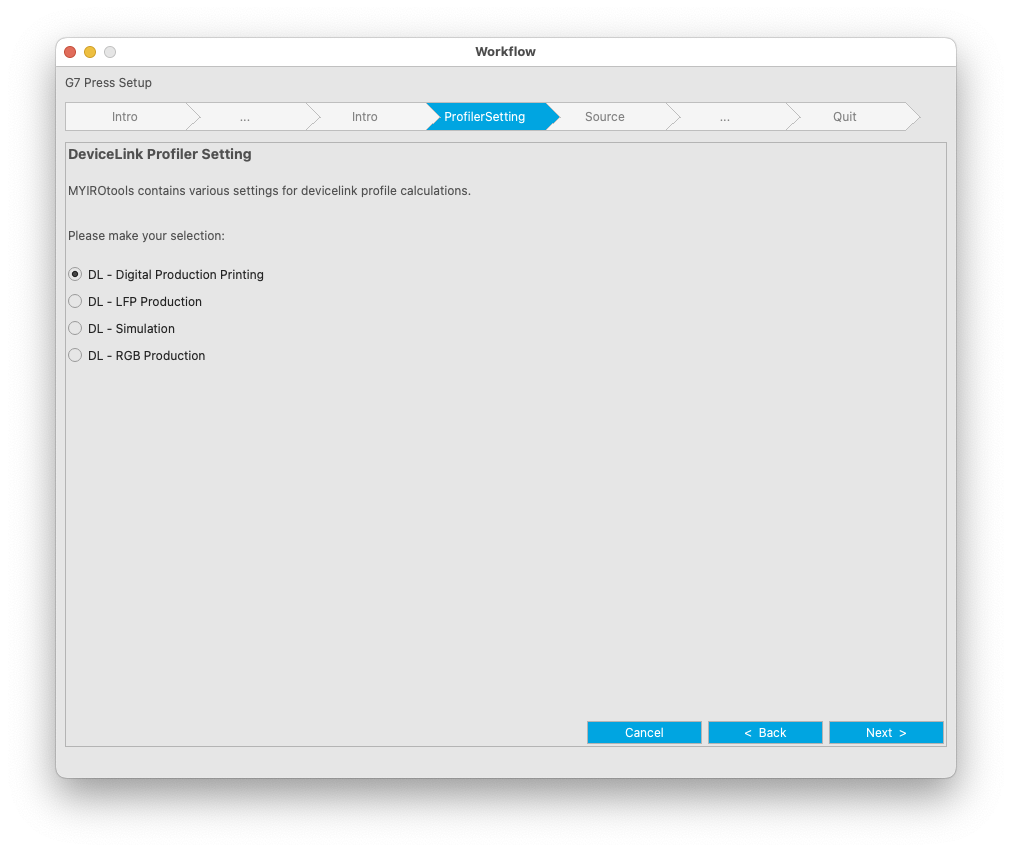

G7 Curves applied as DeviceLink

MYIROtools generates one correction curve per output channel and saves these curves as CMYK2CMYK DeviceLink Profile. This DeviceLink-Profile can be used if the Controller is not capable of applying linearization curves.